文字的描绘可能无法完全捕捉B20AT1500B35AHS500产品的精髓,观看视频,让产品自己向您诉说它的故事。

以下是:B20AT1500B35AHS500的图文介绍

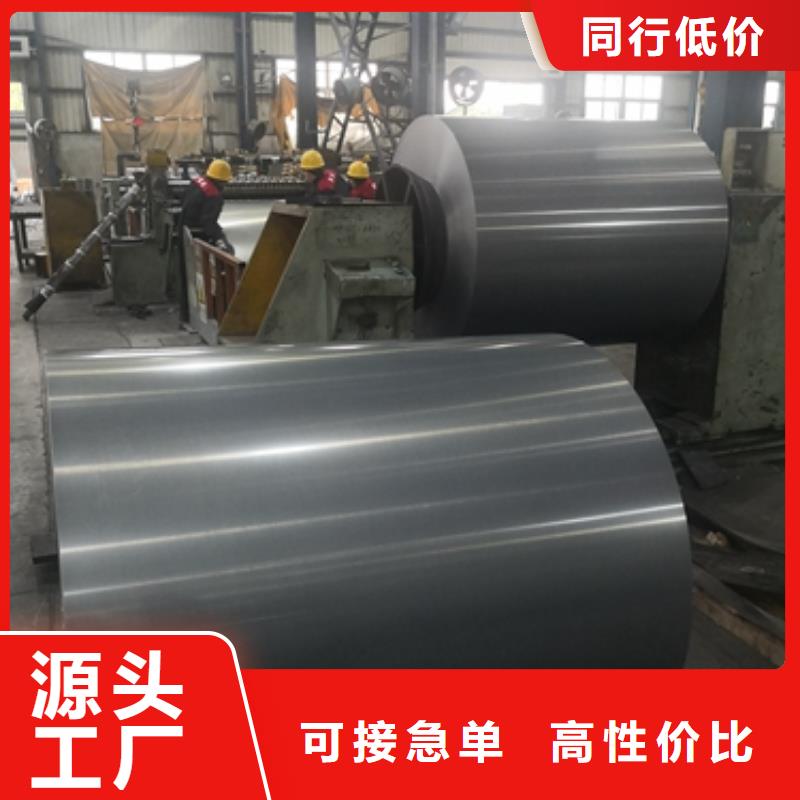

电工钢硅钢片硅钢是一种硅铁合金。用硅钢轧制的片材是电工领域中应用广的软磁材料,因而硅钢片又称电工钢片。硅钢片广泛用于电动机、发电机、变压器、扼流圈、电磁机构、继电器及测量仪表中电机工业大量使用厚度为0.35~0.50mm的硅钢片,用于:中型旋转机,压缩电机,通用马达,小型精密电机,电动汽车,压缩机,通用电机,电源变压器,精密变压器,节能电机,焊机变压器,稳压器,磁性密封器,加速器用电磁铁,汽车电机等;在电信高频技术中常用0.05~0.20mm的薄带钢片,以便更有效地降低涡流损耗。热轧硅钢片厚度为0.35~0.50mm,密度为7.55~7.70g/cm3,多用于大、中、小型交、直流电动机;冷轧无取向硅钢片厚度为0.35~0.50mm,密度为7.65~7.75g/cm3,多用于大型交流发电机、电动机,大、中、小型交、直流电动机;冷轧取向硅钢片厚度为0.23mm 0.27mm 0.3mm 0.35mm,密度为7.65g/cm3,多用于电力变压器、油浸式变压器,干式变压器,电抗器、磁放大器等;冷轧取向薄带厚度为0.05~0.20mm,多用于无线电高频变压器。

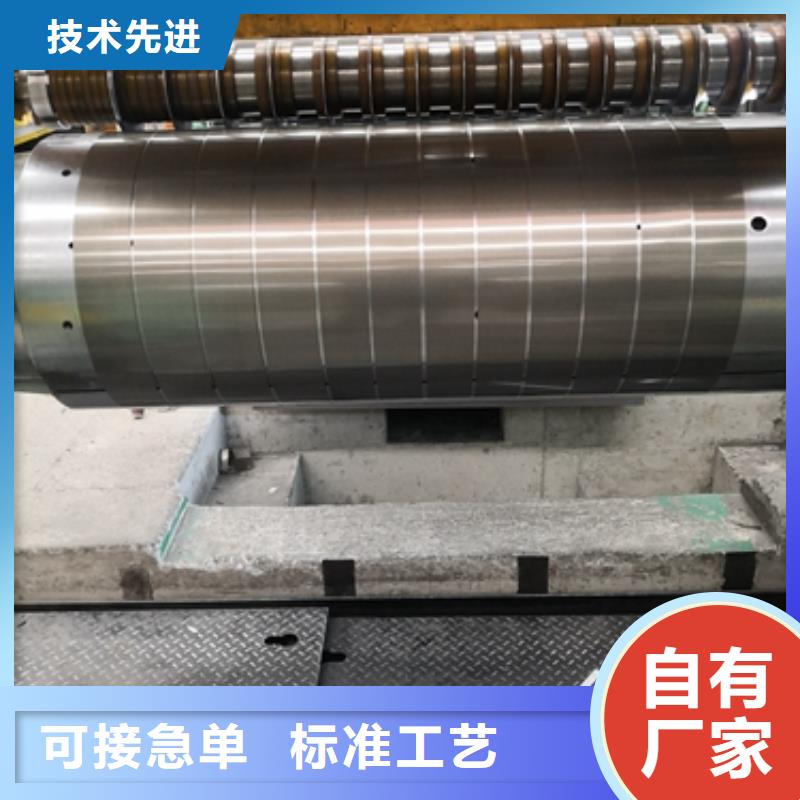

电工钢硅钢片5 剪切适应性钢带应便于进行剪切或冲压 ,以保证在任何位置将钢带剪切成通常的形状。7 技术要求7.1 磁性能在 6.3 条件下提供的产品的磁性能应符合表 3 和表 4 的规定。时效后的磁性能要求,由供需双方在订货时协商,并在合同中注明。表 3 普通型 A、本地应力退火型 AR、本地型 AH 产品磁性能和技术特性类型 牌号公称厚度mm 比总损耗名义值P1.5/50 W/kg 比总损耗P1.5/50 W/kg小磁极化强度J5000a T比总损耗各向异性T1.5/50b %小叠装系数小弯曲次数约定密度kg/dm3普通型B35A2000.352.00 2.00 1.62 ±170.952 7.60B35A210 2.10 2.10 1.62 ±17 2 7.60B35A230 2.30 2.28 1.64 ±17 2 7.60B35A250 2.50 2.45 1.64 ±17 2 7.60B35A270 2.70 2.65 1.64 ±17 2 7.65B35A300 3.00 2.90 1.64 ±17 3 7.65B35A360 3.60 3.20 1.65 ±17 3 7.65B35A440 4.40 3.40 1.67 ±17 3 7.70B50A2300.502.30 2.30 1.64 ±170.972 7.60B50A250 2.50 2.48 1.64 ±17 2 7.60B50A270 2.70 2.65 1.64 ±17 2 7.60B50A290 2.90 2.85 1.64 ±17 2 7.60B50A310 3.10 3.00 1.65 ±14 3 7.65B50A350 3.50 3.20 1.65 ±12 5 7.65B50A400 4.00 3.30 1.66 ±12 5 7.70B50A470 4.70 4.20 1.67 ±10 10 7.70B50A600 6.00 4.70 1.68 ±10 10 7.75B50A700 7.00 5.50 1.71 ±10 10 7.80B50A800 8.00 5.80 1.71 ±10 10 7.80B50A1000 10.00 6.00 1.74 ±8 10 7.85B50A1300 13.00 7.00 1.74 ±8 10 7.85B65A3100.653.10 3.05 1.64 ±150.972 7.60B65A350 3.50 3.45 1.65 ±14 2 7.60B65A400 4.00 3.95 1.66 ±14 2 7.65B65A470 4.70 4.60 1.67 ±12 5 7.65B65A530 5.30 5.20 1.68 ±12 10 7.70B65A600 6.00 5.90 1.68 ±10 10 7.75B65A700 7.00 6.90 1.69 ±10 10 7.75B65A800 8.00 7.90 1.71 ±10 10 7.80B65A1000 10.00 9.90 1.71 ±10 10 7.80B65A1300 13.00 12.90 1.72 ±8 10 7.

鹿程国际贸易(漳州市分公司)是一家以 硅钢为主的经营企业,公司地理位置优越交通十分方便。我们交货及时,价格低,质量优,节假日照常营业。公司凭借雄厚的实力,丰富齐全的规格品种,完善的质量保证,合理的价格,优质的服务,不断地受到新老用户及业内人士的肯定和信任,我们本着及用户之所及,想用户之所想的服务宗旨不断地拼搏,进取,在此对多年来支持我们的各行各业的新老朋友表示由衷的感谢,愿我们今后的合作更加愉快!我们一贯坚持 “ 质量di yi、信誉至上 ” 的生产服务宗旨,奉行 “ 以人为本,诚信立业 ” 的经营理念,秉承 “ 只有专业,才成事业 ” 的发展思路,竭诚为广大新老用户提供优质的产品和优良的服务。

sqyangzi.com

sqyangzi.com